Cortec® offers a variety of water treatment corrosion inhibitors for specialty or multi-use applications. These

include a flash corrosion inhibitor for food can processing, a biobased scale remover for system maintenance,

a float coat for seawater ballast tanks, and versatile products that can be used for wet or dry layup across multiple assets (boilers, other pressure vessels, closed loops, and cooling systems).

VpCI®-308 Series

Water-soluble corrosion inhibitor powder for

yellow metals. Also available in pouch form for

dry layup Provides contact and vapor-phase

protection.

Protects ferrous metals, aluminum, copper, and bronze. Dry layup of boilers, heat

exchangers, and closed- and open-loop

cooling systems. Protects equipment after

hydrostatic testing.

VpCI®-309 Series

Water-soluble corrosion inhibitor powder not

aggressive to yellow metals. Also available in

pouch form for dry layup Provides contact and

vapor-phase protection.

Protects ferrous metals. Not aggressive to

yellow metals. Designed for extended layup

of boilers, heat exchangers, and closedand open-loop cooling systems where

systems will be flushed before recommissioning. Protects equipment after hydrostatic testing.

VpCI®-609 Series

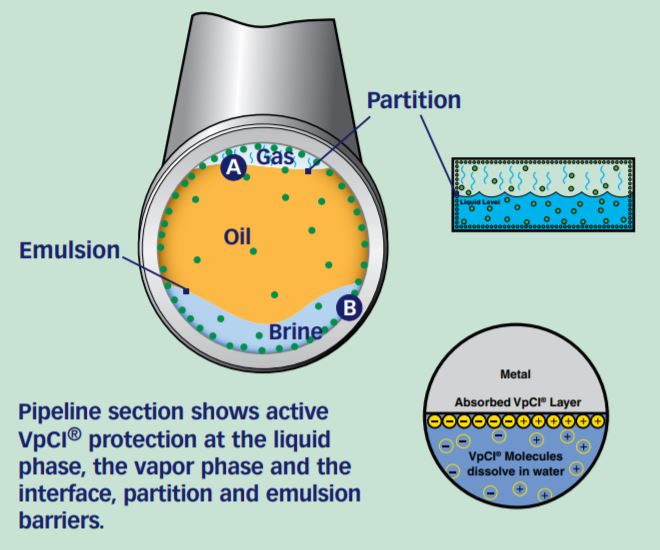

Biodegradable, water-soluble Vapor phase

Corrosion Inhibitor powder for wet or dry corrosion protection of ferrous metals and aluminum. Provides liquid-phase, vapor-phase, and

interface protection. Also available in breathable

EcoPouch® form for dry application.

Protects ferrous metals and aluminum (do

not use with yellow metals). Steam condensate lines, closed circuit heating, and

cooling systems. Hydrostatic testing.

When required, VpCI-609/609S in powder form can be

easily removed by using a low pressure air gun or by a

water rinse. Typically, if applied in aqueous form, the

product does not require removal. If necessary, a simple

water rinse or flush will suffice.

S-11 Series - Organic and inorganic acids rust inhibitor

Corrosion inhibitors for organic or inorganic acids. Suitable replacements for propargyl alcohol.

Aqueous systems with low pH levels, such

as acid pickling and chemical cleaning.

S-14 - Antiscalant - Prevent Caustic Corrosion Derived From The Use of Caustic Soda As Antiscalant

S-14 is a general purpose antiscalant for water treatment

applications. It is very efficient in preventing the formation

of precipitates due to physical or chemical changes on

surfaces in contact with water. S-14 is non-flammable

and non-toxic.

S-14 is primarily formulated for use in conjunction

with Cortec® VpCI corrosion inhibiting formulations in

applications where scale control is being considered.